Attendees at the January, 2015, meeting of the San Lorenzo Valley Amateur Radio Club were treated to presentations by half a dozen of its inventive members.

Buddipole Improvement

Leading the evening, Fred KJ6OOV presented his solution to a weakness of his otherwise useful Buddipole portable antenna mast. The threaded end of the Buddipole mast’s top is affixed to thin-wall tubing using a single set screw. Consequently, supporting off-center loads like an L Antenna rotates the end of the mast and lets the antenna’s horizontal element sag.

Leading the evening, Fred KJ6OOV presented his solution to a weakness of his otherwise useful Buddipole portable antenna mast. The threaded end of the Buddipole mast’s top is affixed to thin-wall tubing using a single set screw. Consequently, supporting off-center loads like an L Antenna rotates the end of the mast and lets the antenna’s horizontal element sag.

Fred machined a custom “spud” from aluminum, epoxied it inside the mast’s thin-wall tubing, and then tripled the number of set screws on the threaded end from one to three. His modified Buddipole mast now supports an off-center L Antenna configuration without rotation.

During discussion, Rich KE1B mentioned that his Buddipole appears to have been constructed differently. So perhaps Buddipole at some point changed its mast design.

Mast Mount & New Tool

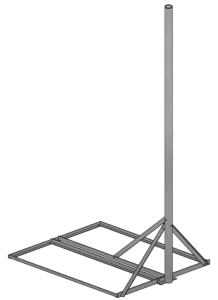

Kerry K3RRY recently learned about a useful kind of mast mount. While preparing to install an antenna mast for a project on a flat roof at UCSC, the director of facilities asked that he use a “non-penetrating roof mount” on the building’s asphalt and gravel roof. Kerry discovered that such mounts are popular in commercial installations for everything from short masts to satellite dishes.

Kerry K3RRY recently learned about a useful kind of mast mount. While preparing to install an antenna mast for a project on a flat roof at UCSC, the director of facilities asked that he use a “non-penetrating roof mount” on the building’s asphalt and gravel roof. Kerry discovered that such mounts are popular in commercial installations for everything from short masts to satellite dishes.

The mount that Kerry used (Baird Mounting Systems B3-34×40) is constructed from steel 90-degree angles, welded and galvanized. The mount requires ballast (concrete blocks) to prevent it from blowing over or sliding on the roof. Baird will perform an analysis that uses the location, height, and surroundings of the supporting building and then recommends a ballast weight. For Kerry’s application (a UHF vertical on an 8-foot mast), the ballast needed to weigh at least 91 pounds. Four concrete blocks from a nearby hardware store sufficed.

In other work, while preparing for some tower work, Kerry discovered that one can buy a “powered ratchet wrench.” Kerry already has a set of ratcheting box wrenches, which he finds very useful while working on a tower, but the amount of work to be done recently on one tower benefitted from a power tool. The Milwaukee M12 Cordless 3/8″ Lithium-Ion Ratchet is lightweight, and its small battery required no recharging on site. A set of six-point deep sockets from Sears completed the investment.

Printed Circuit Boards & Code Oscillator

Tuck AF6GQ makes his own printed-circuit boards(PCBs). At the meeting he presented his home-made double-sided PCB developer. The developer uses two arrays of ultraviolet LEDs to expose the photoresist on both sides of pre-treated PCB blanks simultaneously. A microcontroller-based timer controls the exposure.

Tuck’s grandson presented his Morse Code oscillator project. It is hand soldered on a perf board, and when it is complete, it will reside in an Altoids tin.

Resistance is . . . Necessary?

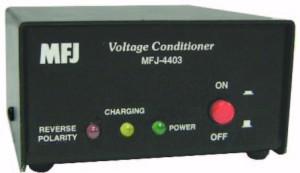

Sam WB6RJH demonstrated his discovery of a power-supply configuration that fails when it is assembled using a low-resistance power cable! He planned to use an MFJ power conditioner to clean the output of an old Radio Shack switching power supply. Connecting the supply to the conditioner using a long power cable was successful, but connecting the two devices using a short cable caused the power supply to trip off during power up! The MFJ power conditioner limits inrush current based on the voltage across its 4-farad supercapacitor. When the inrush-current-limiting resistor switches out of circuit, the power supply trips off. Apparently the added resistance of a longer and narrower power cable added just enough resistance to prevent the power supply from detecting an over-current event.

Sam WB6RJH demonstrated his discovery of a power-supply configuration that fails when it is assembled using a low-resistance power cable! He planned to use an MFJ power conditioner to clean the output of an old Radio Shack switching power supply. Connecting the supply to the conditioner using a long power cable was successful, but connecting the two devices using a short cable caused the power supply to trip off during power up! The MFJ power conditioner limits inrush current based on the voltage across its 4-farad supercapacitor. When the inrush-current-limiting resistor switches out of circuit, the power supply trips off. Apparently the added resistance of a longer and narrower power cable added just enough resistance to prevent the power supply from detecting an over-current event.

And the Rest

John AC6SL presented a Powerpoint presentation of five recent projects. The presentation, with photos, covers these topics:

- Astron Power Supply Repair

- PVC-Tubing Equipment Shelf

- LOTW log scripts

- quisk Panadapter

- Resonant Speakers